At Original Webbing, we are committed to delivering products of the highest quality. Our stringent quality control measures ensure that every item leaving our factory meets the most demanding standards. We employ state-of-the-art testing instruments and rigorous processes to guarantee the excellence and reliability of our products. Below is some of the testing performed in-house at Original Webbing. In cases where there is no standard publicly available for reference, a test method will be developed internally or through the customer to verify performance.

In-house Laboratory Test

Through our Lab Value Detector, we achieve accurate color reproduction. Assessing hue, saturation, and brightness, our textiles exhibit consistent and precise color representation.

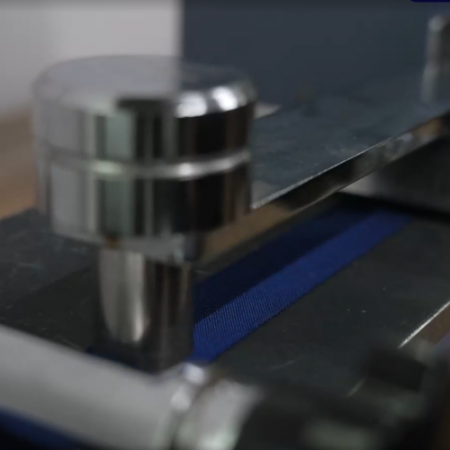

By subjecting our textiles to controlled dry and wet friction, we can evaluate their resistance to wear and tear. This meticulous testing guarantees that our products can withstand the demands of everyday use.

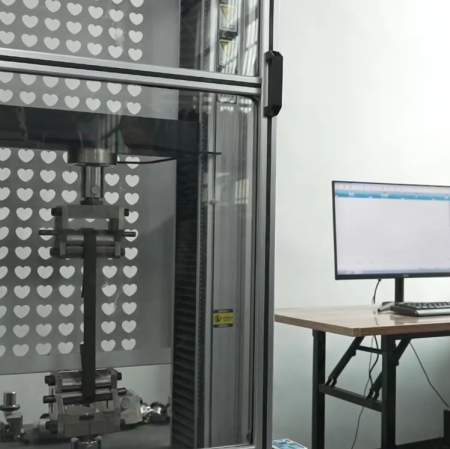

Tensile testing is to ensure strength and consistency. Webbing capstan grips with a double capstan design enable easy loading, ensuring accurate and comprehensive testing of the material's tensile properties.

This testing utilizes cutting-edge constant wet and humidity test machines, replicating real-world conditions.This process ensures our products maintain their integrity and exhibit exceptional wear resistance.

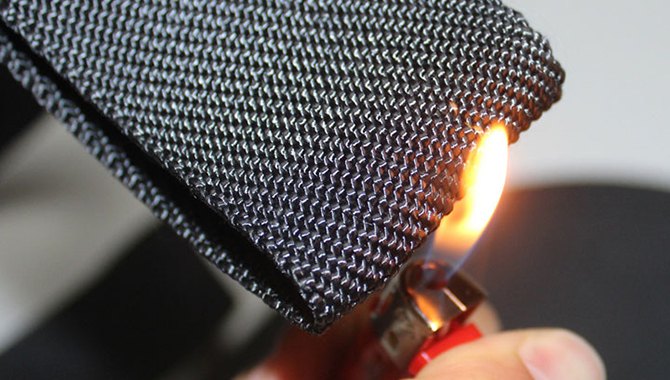

We conduct this testing to ensure the utmost safety of our products. Through rigorous assessments, we evaluate their resistance to ignition and the spread of flames.

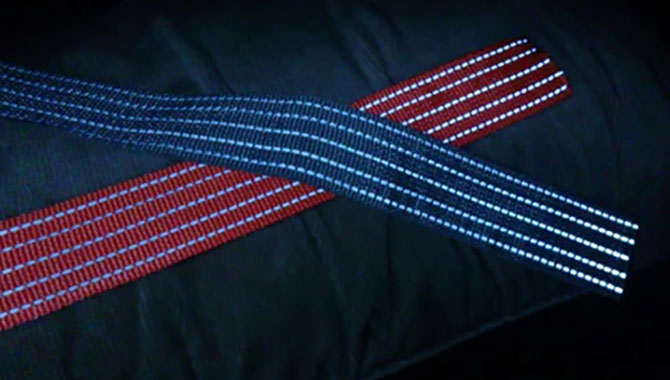

We perform waterproof tests to validate the water resistance capabilities of our products. By subjecting them to controlled water exposure under varying conditions, we assess their ability to repel moisture and maintain their functionality.

Test Performance

- Friction Test

- Waterproof Test